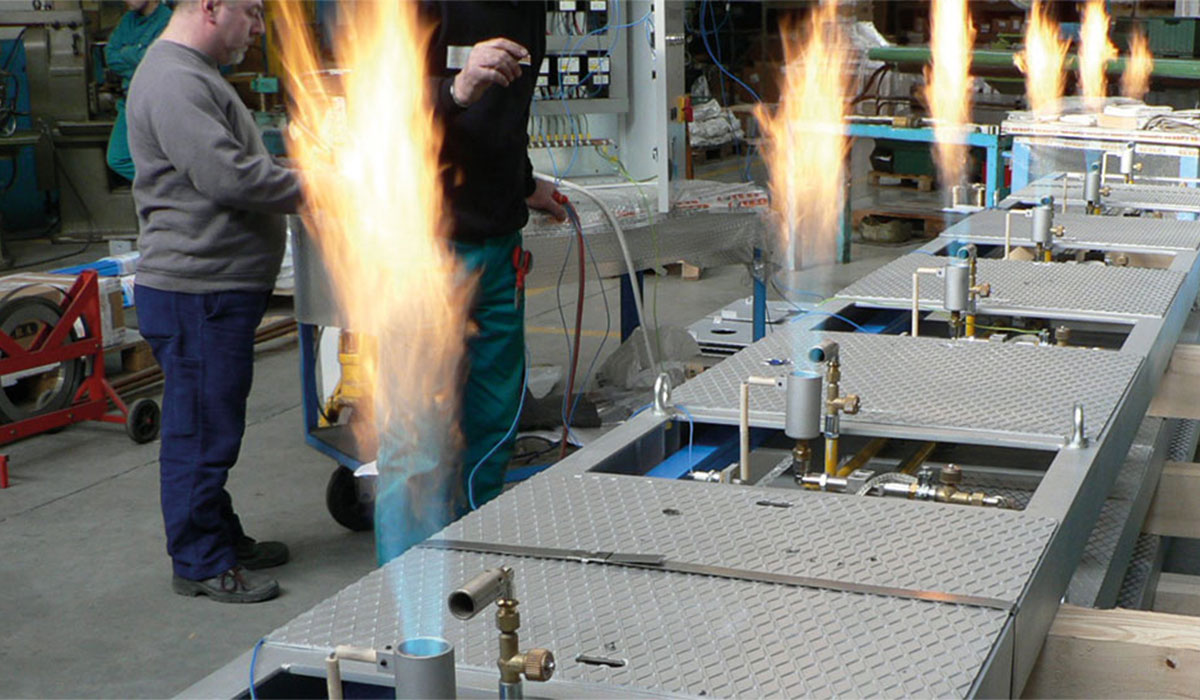

A.L.B.A.’s special heating systems are designed and manufactured in order to allow heating of large pipes components, flanges, plates prepared for welding process, surface inserts or junctions.

They use ‘manifolds’ modular burners holders assembled by means of a fulcrum pin that allows to set up polygons adapting to the profile of the piece to be heated. Burners for manifolds have a high thermal capacity working with a mix of air and combustible gas (methane or propane) and a reducing flame.

A.L.B.A. can supply the complete heating system which includes a regulating panel for air and combustible gas, flameproof and self-extinguishing flexible hoses, safety valves and flashback arrestors, quick couplings for fast and easy assembling/ dismantling, manifolds in different quantity and length according to customer needs.The system can be also equipped with an electronic control device in order to automatically check and regulate the desired heating temperature.

A.L.B.A. also designs and manufactures heating and drying systems for tundishes, ladles, etc. which include steel supporting structure, complete fluids regulating station, control panel, feeding hoses, and safety devices.

A.L.B.A.’s heating and drying systems are developed according to the UNI EN ISO 9001:2015 quality standard.